Introduction/ Motivation

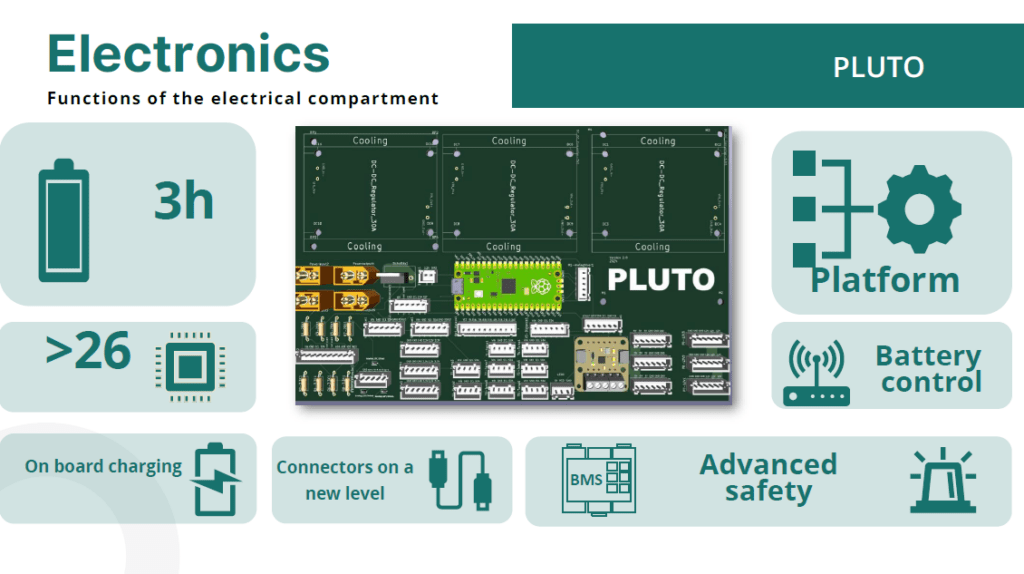

During our user roadmap, we defined different functions, which should be fulfilled by Pluto and which are directly influencing the electrical system of Pluto. The functions, which are influencing the electrical system are the following:

-

- Enough battery life time

-

- Implement different kind and types of sensors

-

- On-board charging

-

- Fast connection of sensors and other electrical equipment

-

- Advanced safety

-

- Battery control systems

- Platform thinking

During defining the functions, we decided also that we should use an PCB-board in Pluto to reduce the amount of cabling inside Pluto. Why is that necessary?

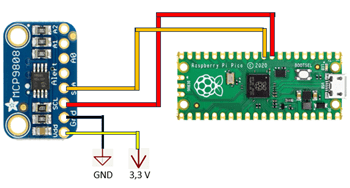

Let’s take as an example a temperature sensor (MCP9808). The following pins from the temperature sensor are required for our application:

-

- SCL

-

- SDA

-

- VIN

-

- GND

So normally you would need one cable per pin, which you need to connect with our controller. In our case, the Rasberry Pi pico 2040. At the moment we are planning to use more than 26 sensors in Pluto. That would result in a big number of cables laying in Pluto.

To avoid that, we decided to create our own board as measurement to reduce the number of cabling.

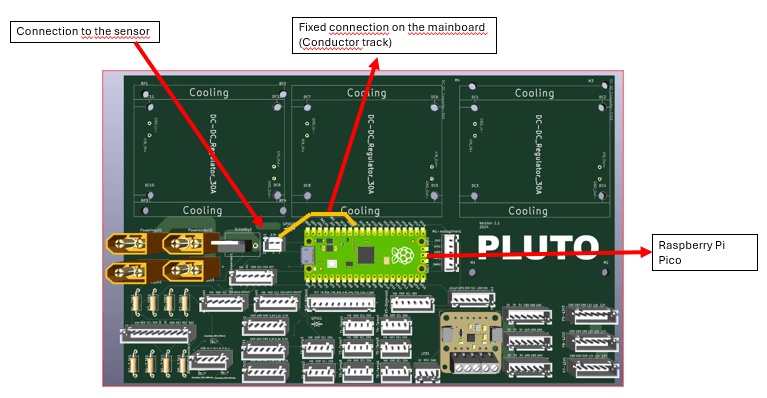

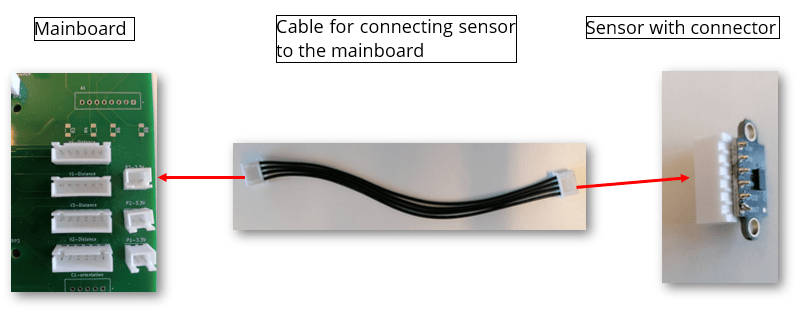

Our plan was to place connectors on the board. These have fixed connections (conductor tracks) over the board with the Rasberry Pi Pico. The sensor can then be placed on any position on Pluto.

The cables which go out of the sensor are then bundled in a plug, which fits to the connector on the board.

The electrical circuit and the PCB Layout were created with the open-source software KiCad 7.0.

Schematic of the electrical system

To show the interconnections within the electrical system, the following chart was created. It shows also all the main components of the electrical system:

Mainboard

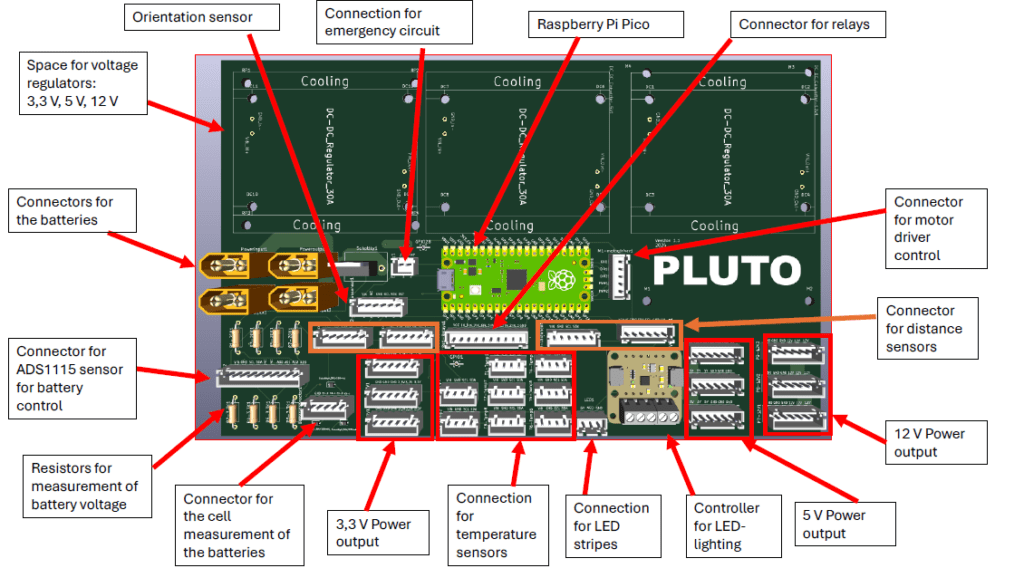

The mainboard is like the „brain“ of the robot. It incorporates all the connectors to the different sensors and some main components, which are required for all real-time calculations in our Pluto. Also it serves like a Platform, which can easily be expanded by other intakes with new functions.

Structural Layout

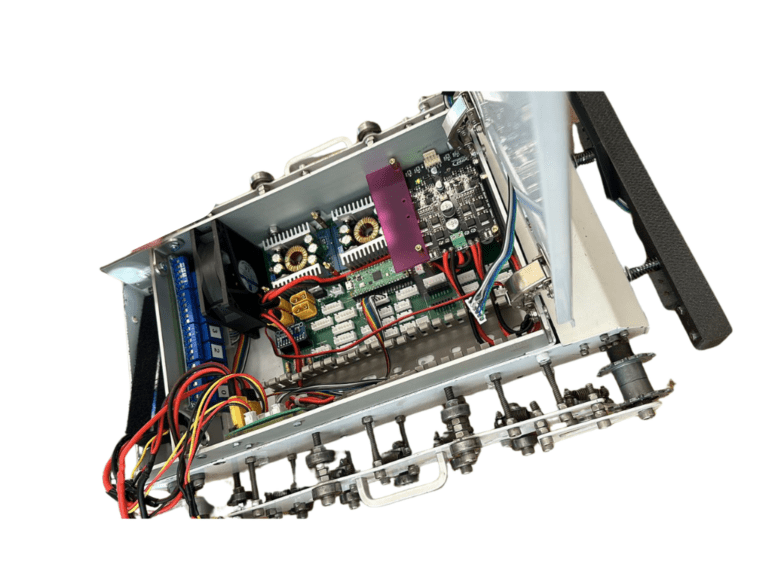

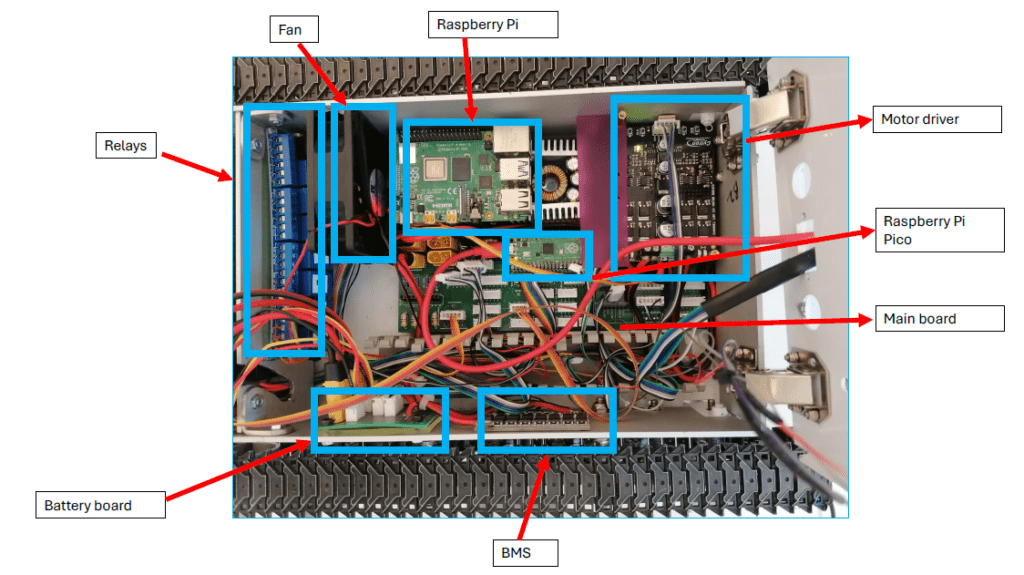

Next to the main board, also other components are required for Pluto:

Outlook

Although the Pluto electronics were working, there were still some problems, which will be explained in the following:

Emergency-off system:

The emergency system is using 5 opener switches, which can interrupt the connection. In case one of them is interrupted, it opens the circuit. This is working most of the time correctly. But there are some loose contacts or other reasons, so that the connection is interrupted without any reason. So, the Raspberry Pi is realizing an emergency switch off, without touching one of the emergency switches. This issue needs to be fixed.

Also it would be estetically more pleasing if each switch would be wired up with a separate plug, so that there are no wires conducted through the inner of Pluto.

Distance sensors:

The Pluto uses four distance sensors, to check for upcoming objects up front and in the back, which are integrated into the fenders. Two of these sensors have gotten hot, so they need to be unplugged. This needs to be fixed. Probably measuring voltagelevels and currents will help to fix the issue.

Mainboard re-design:

Currently the mainboard is working correctly. If any additional functions should be implemented by the next intake and a new mainboard will be manufactured, it needs to be taken care of, that there is a collision between the mainboard and one of the screws of the housing. This means, the shape of the mainboard has to be re-designed.

Functional test of the mainboard:

The electronics have not been properly tested. So it is still necessary to do a extensive validation test with all electronics as well as the software, to ensure that all sensors are working correctly.

Platform thinking:

The current Pluto platform offers the possibility to expand the functions of our robot. Additional functions like a freezer, an electrical lock or even more LED’s are possible.

Test of on-board charging:

The BMS (Battery Management System) ensures the safety of both batteries during the charging process. This enables charging the batteries, while they are installed. This has not been tested yet.